So I ran into my first snag.....About a year and a half ago when I was designing my spindles, I found all the dimensions on line for the Wilwood Pro spindles. So I used that geometry to make mine, perfect, Right!. Well the problem is I used the Wilwood 2" drop spindle figuring I would need all the drop I could get, WRONG! The truck is actually Too Low! The combination of the crossmember location, and the shape of the chassis, makes the center of the chassis 3" off the ground.... The front section is fine at 5", but 3" is not enough clearance for New England roads. So there are a couple ways I could fix this, I could notch the chassis where the crossmember mounts, but this would weaken the frame, with 500+HP on tap, really not an option. I could modify my existing spindles to gain about 1", but still not enough. The right way to fix this is to design new 2" raised spindles (or really "Stock" height). It sucks, but it's the right way to do it. Actually the designing is the easy part, having the parts machined can get expensive, luckily I have a friend that runs a machine shop, and treats me good on price. So, the design is done, and parts are being cut, in the meantime, I'm starting on cleaning up the rear frame rails.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tincup's D100

- Thread starter Tincup

- Start date

GoosePoop

Member

This is a mustang 2 type set up? Solidworks?

I'm glad to hear that your fixing the issue the right way . So many time's we get in a hurry to get something done that we might cut corners just to call it done . We live and we learn , do it right and move on to the next thing on the list . You'll be tearing down the road in no time !So I ran into my first snag.....About a year and a half ago when I was designing my spindles, I found all the dimensions on line for the Wilwood Pro spindles. So I used that geometry to make mine, perfect, Right!. Well the problem is I used the Wilwood 2" drop spindle figuring I would need all the drop I could get, WRONG! The truck is actually Too Low! The combination of the crossmember location, and the shape of the chassis, makes the center of the chassis 3" off the ground.... The front section is fine at 5", but 3" is not enough clearance for New England roads. So there are a couple ways I could fix this, I could notch the chassis where the crossmember mounts, but this would weaken the frame, with 500+HP on tap, really not an option. I could modify my existing spindles to gain about 1", but still not enough. The right way to fix this is to design new 2" raised spindles (or really "Stock" height). It sucks, but it's the right way to do it. Actually the designing is the easy part, having the parts machined can get expensive, luckily I have a friend that runs a machine shop, and treats me good on price. So, the design is done, and parts are being cut, in the meantime, I'm starting on cleaning up the rear frame rails.

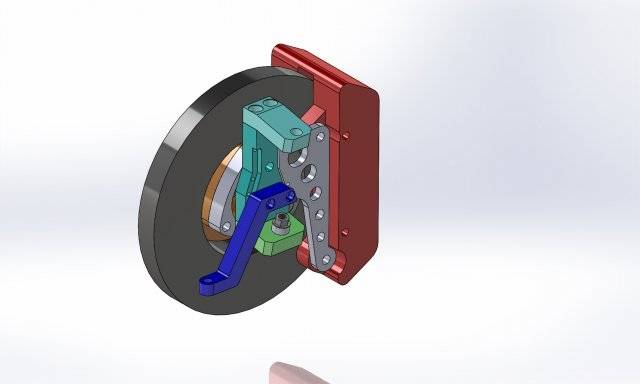

View attachment 6204

Yes & Yes...This is a mustang 2 type set up? Solidworks?

GoosePoop

Member

Foregive me, but I really want to catch up to speed here on your build. You are designing your own spindles (awesome) but I have to ask why? Does this suspension kit not offer an appropriate spindle that would work? or is it because you want to run the wilwood system? thanks

I had to design my own spindles so that I could adapt the factory Dodge SRT10 brakes ( 15" rotors front & 14" rotors rear) to a Mustang 2 type suspension.Foregive me, but I really want to catch up to speed here on your build. You are designing your own spindles (awesome) but I have to ask why? Does this suspension kit not offer an appropriate spindle that would work? or is it because you want to run the wilwood system? thanks

GoosePoop

Member

Got it! Now I am in the loop. I will enjoy watching your progress. Such a great build. I am a Auto Cad/ Solid Works teacher so I was very interested in someone taking on the challenge of designing their own spindles. If you don't mind sharing...whats a ball park figure to have a set made?

GoosePoop

Member

Fantastic!!! How about a little write up about the install and how to make sure the geometry is correct? Can we get a pic of the axle housing assembly for the swing arm? Love this build

Dam ! Nice job ! I'm definitely liking the way you think and your approach to a build . May I ask what you do for a living ? If it's not building cars then it should be .

So, in preparation for the C-notch, I wanted to clean up the frame rails. After removing all the unnecessary brackets, I welded up all the holes, 35 each side! Then boxed the rails so I have something to weld the C-notch to.

ricks_RR

Active Member

very nice work thanks for the pic

7mopar

Well-Known Member

So that is a c notch! You going to need to box the top of the notch back to the front frame section?

Something like that would work , for sure !  The only reason why I asked ( and I know it's not my truck ) but I hate it when all the frame work and such is exposed inside the bed . I like a nice clean or finished look myself . But that's just my taste and as far as I'm concerned your doing great so far !

The only reason why I asked ( and I know it's not my truck ) but I hate it when all the frame work and such is exposed inside the bed . I like a nice clean or finished look myself . But that's just my taste and as far as I'm concerned your doing great so far !